Our Products ➼ Loading Bay Equipment ➼ Loading Lift Tables ➼Loading Lift Tables

Build Enterprises India Loading Lift Tables comply with the European Safety of Machinery standards EN 292, Machinery Directive 2006/42/CE and Safety requirements for lift tables EN 1570.

All models include:

➼ Aluminium safety bar, stopping descent of the platform on contact with obstructions

➼ Safety clearance between scissors to prevent trapping during operation

➼ Safety check valve to stop the lift table lowering in the unlikely event of a hose break

➼ Protection against overloading

➼ Low voltage control box with up-down buttons and emergency stop

➼ Maintenance props (for safe maintenance operation)

➼ Removable lifting eyes to facilitate handling and lift table installation.

Used to load and unload vehicles by pedestrian or fork lift trucks without a loading dock and designed to operate with maximum safety for off-centred crossing loads

Technical features:

- Safety tread top platform surface

- Max. 15 cycles per hour, one shift a day (for more intense operations please consult with us)

- Single acting hydraulic cylinders with drainage

- Upper travel limit switch

- Check valve on each cylinder for higher stability

- Self lubricating bearings on pivot points

- Hydraulic power pack inside the table provided with relief valve against overloading and compensated flow valve for controlled lowering speed

- Electrical equipment controlled by electronic system, with low voltage transformer and thermal overload protection

- Wide range of options available such as wheel stops, goal post barriers, safety handrails, manual bridge plates etc. to meet specific requirements

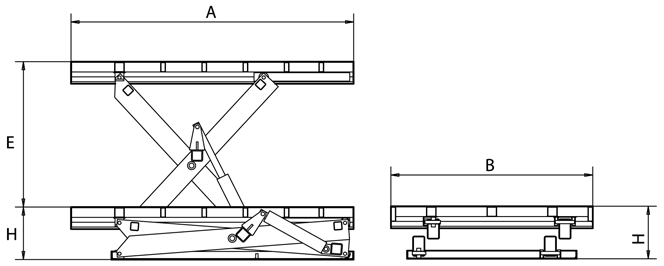

Technical Specifications

| Model Stroke | Capacity (in Kg) | Stroke E mm | Platform A x B mm | Collapsed Height H mm | Motor (Kw) | Cylinder (nos) |

|---|---|---|---|---|---|---|

| SLT.40.T000 | 4000 | 1600 | 2500 x 2000 | 500 | 4 | 2 |

| SLT.40.T010 | 4000 | 1600 | 3000 x 2000 | 500 | 4 | 2 |

| SLT.40.T020 | 4000 | 1800 | 3000 x 2000 | 550 | 4 | 2 |

| SLT.40.T030 | 4000 | 1800 | 3000 x 2200 | 550 | 4 | 2 |

| SLT.40.T040 | 4000 | 1800 | 3500 x 2200 | 550 | 4 | 2 |

| SLT.40.T050 | 4000 | 2000 | 3500 x 2000 | 550 | 4 | 2 |

| SLT.40.T060 | 4000 | 2000 | 3500 x 2200 | 550 | 4 | 2 |

| SLT.40.T070 | 4000 | 2000 | 4000 x 2200 | 550 | 4 | 2 |

| SLT.60.T000 | 6000 | 1500 | 2500 x 2000 | 550 | 4 | 2 |

| SLT.60.T010 | 6000 | 1800 | 3000 x 2000 | 600 | 4 | 2 |

| SLT.60.T020 | 6000 | 1800 | 3000 x 2200 | 600 | 4 | 2 |

| SLT.60.T030 | 6000 | 1800 | 3500 x 2200 | 600 | 4 | 2 |

| SLT.60.T050 | 6000 | 2000* | 3500 x 2000 | 600 | 4 | 2 |

| SLT.60.T060 | 6000 | 2000* | 3500 x 2200 | 600 | 4 | 2 |

| SLT.60.T070 | 6000 | 2000 | 4000 x 2200 | 600 | 4 | 2 |

| SLT.80.T000 | 8000 | 1500 | 2500 x 2000 | 600 | 4 | 2 |

| SLT.80.T010 | 8000 | 1800 | 3000 x 2000 | 650 | 4 | 2 |

| SLT.80.T020 | 8000 | 1800 | 3000 x 2200 | 650 | 4 | 2 |

| SLT.80.T030 | 8000 | 1800 | 3500 x 2200 | 650 | 4 | 2 |

| SLT.80.T050 | 8000 | 2000 | 3500 x 2000 | 650 | 4 | 2 |

| SLT.80.T060 | 8000 | 2000 | 3500 x 2200 | 650 | 4 | 2 |

| SLT.80.T070 | 8000 | 2000 | 4000 x 2200 | 650 | 4 | 2 |

| SLT.A0.T000 | 10000 | 1500 | 2500 x 2000 | 650 | 5.5 | 2 |

| SLT.A0.T050 | 10000 | 2000 | 3500 x 2000 | 700 | 5.5 | 2 |

| SLT.A0.T060 | 10000 | 2000 | 3500 x 2200 | 700 | 5.5 | 2 |

| SLT.A0.T070 | 10000 | 2000 | 4000 x 2200 | 700 | 5.5 | 2 |